Meet the Next Generation of

Versamill Precision Dental Machining Centers

Introducing Versamill

Our new SPEED Series of Precision Dental Mills share some of the most important features a high precision machine must provide to assure it is capable of reliably and consistantily producing the highest quality restorations with the minimum amount of profit-stealing and error prone post-machiing handwork. It's the life blood of your machine and a large part of the SPEED Series DNA.

Axis Drive System

Axsys Advantage: DNA Strand 2High-precicion CNC machines such as SPEED Versamill's utilize precision ballscrews in a closed-loop system powered by high-torque servo motors supported by absolute encoders. This system is superior and requires signifianly less machine calibration than lower-quality systems using stepper motors or servo motors with incremental encoders.

Spindle Drive

Axsys Advantage: DNA Strand 3The spindle is the heart of any CNC machine and SPEED Versamil's utilize the best in the business. SPEED spindle drives are selected for consistant, high-torque over the useable rpm range. It is this aspect of a spindle that is more important than power rating. SPEED spindles are liquid cooled 3X hybrid bearings to maintain precision and longer life.

Machine Control

Axsys Advantage: DNA Strand 4Effectieve high-speed machine control systems require high-block processing rates to keep up with the high-speeds required for dental applications. These controls should be built-in and provide access to the control API thereby allowing future expansion and automation. SPEED Machine controls are developed in the USA.

Products

Introducing the Versamill SPEED

Assembled in the USA

All Versamill 7 Series machines are assembled in our Traverse City facility using foreign and domestic components. This includes the machine control which is developed in the USA.

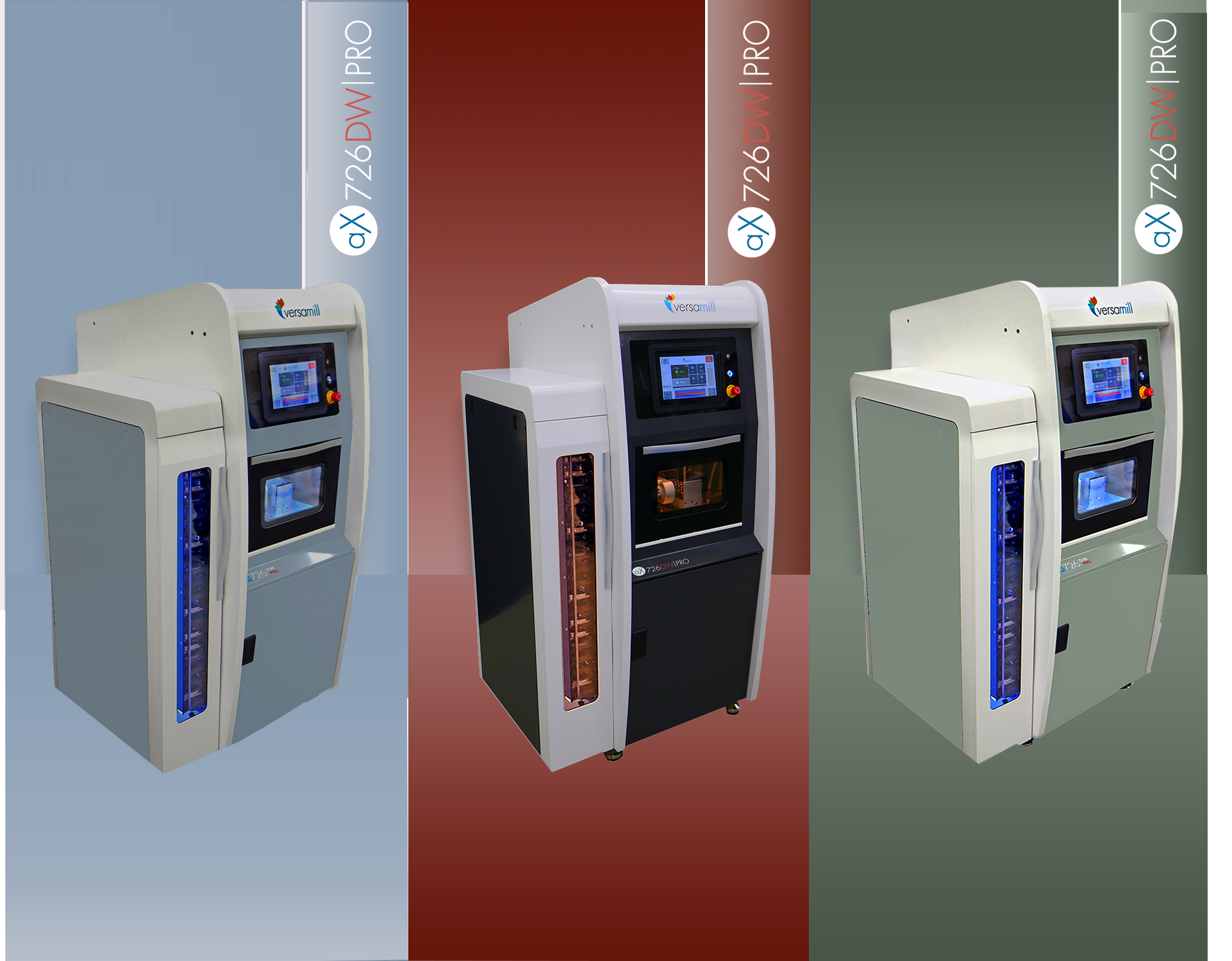

WITH AUTO-LOADER

The AX 726DW PRO is a dry or wet processing machine that features an 18-position robotic auto-loader. These robotic loaders have stood the test of time and are free from the frequent failures of the traditionally, heavily mechanized auto-loaders available on the market today.The extreme stability of the AX 726DW PRO together with its high-torque spindle and servo motor driven drives enable the processing of virtually any prosthesis made of the vast choice of dental materials available today and tomorrow–all with fine detail and clean, thin restorative margins.

HIGHLIGHTS

AX 726DW PRO highlights include:

WITH MANUAL-LOAD

The AX 726 DW is a dry or wet processing machine that has all the features of the AX 726DW PRO in a manual load configuration.The extreme stability of the AX 726 DW together with its high-torque spindle and servo motor driven drives enable the processing of virtually any prosthesis made of the vast choice of soft dental materials available today and tomorrow–all with fine detail and clean, thin restorative margins.

HIGHLIGHTS

AX 726 DW highlights include:

Versamill SPEED 7 Specifications

The Benefits of Wet Milling Zirconia

Contrary to claims to the contrary, there are many benefits to wet-machining zirconia. These benefits extend beyond the added expense and noise associated with the required filtration and vacuum systems required for dry milling applications. These vacuum and filtration systems, while removing a large amount of the caustic zirconia dust generated by the machining process, do not remove all of the dust- the balance of which becomes air born in the lab or dental office environment and creeps into machine components thereby compromising or shortening their operational lives. Zirconia sludge (the mixture of zirconia and water) is by far easier to deal with than dry zirconia dust, does not infiltrate machine components and is significantly less destructive to machine components than caustic and abrasive dry zirconia swarf (by-products of the machining process). Users not only enjoy longer machine and tool life, lower operating expense, and reduced system maintenance, but also realize the benefits of highly detailed and lustrous post-sinter units, superior surface finishes and sharp margins without extensive margin reinforcement- “do-overs" due to chipped or blown out margins are very rare and if present, usually attributed to worn tooling. We recommend washing/cleaning out the machining area, of any mill, machining any material, be done daily as part of a preventative maintenance program. It does not take very long and is not difficult to do. Flushing with a water hose works well. Use of compressed air should be done carefully with low pressure, especially with "dry" machines that do not have adequate sealing of the machining enclosure. Do this and the machine will reward you with smooth operation and longer, care-free life.

Zirconia Drying Times

| Single (70°C)): | 15 minutes+ |

| Single (140°C)): | 5-10 minutes |

| 2-4 units (70 °C): | 40 minutes+ |

| 2-4 units (140°C): | 25 minutes+ |

| 5+ units (70°C): | 50 minutes+ |

| 5+ units (140°): | 25 minutes+ |

|

|

|

|

| Specification | Versamill 5X-300D | Versamill 4X-100 | Versamill 5X-200 |

|---|---|---|---|

| Travel Limits (X, Y Z Axis) | 145 x 110 x 85 | 250 x 116 x 110 | 330 x 146 x 145 |

| Travel Limits (Rotary Axis) | ±180° B-Axis, ±30° A-Axis | 360° A-axis | ±180° A-axis, ±30° B-axis |

| Number of Axes | 5 Simultaneous | 4 Simultaneous | 5 Simultaneous |

| Accuracy | ±10.0µm | ±5.0µm | ±5.0µm |

| Repeatability | ±5.0µm | ±3.0µm | ±3.0µm |

| Automatic Tool Changer | 12 Tools w/Tool Breakage Sensor | 8 Tools w/Tool Breakage Sensor | 15 Tools w/Tool Breakage Sensor |

| Spindle | 60,000, 0.5kW, Air Cooled | 60,000 rpm, 1.4kW, Air Cooled | 60,000 rpm, 3.0kW, Air Cooled |

| Circular Material Block | 98.3Ø Disc | 98.3Ø Disc | 98.3Ø Disc |

| Machine Dimensions (W x L x H) | 540mm x 580mm x 630mm (machine only) | 623mm x 780mm x 1735mm | 745mm x 830mm x 1765mm |

| Installation Space (W x L x H) | 1220mm x 900mm x 1800mm (w/optional table) | 1100mm x 800mm x 2005mm | 1220mm x 900mm x 2025mm |

| Axis Drive System | Stepper motors, ball screws w/anti-backlash ballnuts & linear guides | Servo motors, ball screws w/anti-backlash ballnuts & linear guides | Servo motors, ball screws w/anti-backlash ballnuts & linear guides |

| Weight | 90 kg | 300 kg | 405 kg |

| Gross Weight (For Shipment) | 175 kg | 365 kg | 475 kg |

| Drive Mechanism | Ball Screw | Ball Screw | Ball Screw |

| Way System | Linear Guide s | Linear Guide | Linear Guide |

| Power Supply | 120-240 VAC 50/60 Hz Single Phase,5.5 amps | 220-240 VAC 50/60 Hz Single Phase, 15 amps | 220-240 VAC 50/60 Hz Single Phase, 15 amps |

| Clamp Diameter/Tool Shank | 4.0mm | 6.0mm | 6.0mm |

| Materials | Zirconia, PMMA, PEEK, Pekkton, Nano-composits, Lava Ultimate, Resin, Wax and more | Cr-Co, Ni-Cr, Titanium, Zirconia, PMMA, Glass-ceramics, Lava Ultimate, Resin, Wax and more | Cr-Co, Ni-Cr, Titanium, Zirconia, PMMA, Glass-ceramics, Lava Ultimate, Resin, Wax and more. |

| Indications | Crowns, Copings, Bridges, inlays/onlays, Splints, hybrid abutments, hybrid bars & more. | Inlays and Onlays, Crowns, Copings, Bridges, Custom Abutments & more. | Inlays and Onlays, Crowns, Copings, Bridges, Custom Abutments, Bar Overdentures & more. |

In the News

|

Milled Titanium Splinting Offers Superb Fit and Fast Appointment Time | In-office laboratory benefits from precision, versatility of Versamill 5X200 | Robin D. Henderson, DMD, MS | Oklahoma Ctr for Implants & Periodontics | READ |

|

DENTIST USES PREMIUM MACHINERY FOR IN-HOUSE LABORATORY |

Ability to mill precision abutments same-day with Versamill 5X helps fulfill mission | Khaldoun Attar, DDS | Sun Dental & Denture | READ |

|

Mechanical Skills Help Drive Former Racecar Crew Chief's Laboratory | Open system, ability to customize are keys when purchasing CAD/CAM equipment | John Noel, CDT | Noel Laboratories Inc. | READ |

- Address: 29627 West Tech Dr.

Wixom, MI 48393 - Toll Free: + 1 (855) 687 7941

- Office: + 1 (248) 926 8810

- Fax: + 1 (248) 926 9085

- Email:

Recent Posts

Axsys Dental Solutions Annouce TrimExpert

The First Ever Automated Applicance Trimming Solution

New Versamill 5X450 Announced

Axsys Dental Solutions Announces The Immediate Release Of the New Versamill 5X450useful links

- Whitepaper: Construction Characteristics of an Effective Dental Milling Machine

- 10 Questions to Ask Before Purchasing a New Dental Milling Machine

- Axsys Dental Solutions Personal Care Support Program

- Axsys Dental Solutions Corporate Datasheet

- ROI Calculator: Restorative

- ROI Calculator: Custom Abutments