- Customer Care | Need help? Call us: (855) 687 7941

Menu

Close

- Home

- Products & Services

Company

The Axsys Advantage

Financing & Promotions

News & Testimonials

Product Portfolio

Dental Machining Centers

VERSAMILL CLASSIC COLLECTION

VERSAMILL SPEED COLLECTION 3 SERIES

VERSAMILL SPEED COLLECTION 7 SERIES

VERSAMILL SIGNATURE COLLECTION

Chairside Machining Centers

Consumable Products

- LEARNING ZONE

- Testimonials

- Blog

- Contact Us

- Home

- Products & Services

Company

The Axsys Advantage

Financing & Promotions

News & Testimonials

Product Portfolio

Dental Machining Centers

VERSAMILL CLASSIC COLLECTION

VERSAMILL SPEED COLLECTION 3 SERIES

VERSAMILL SPEED COLLECTION 7 SERIES

VERSAMILL SIGNATURE COLLECTION

Chairside Machining Centers

Consumable Products

- LEARNING ZONE

- Testimonials

- Blog

- Contact Us

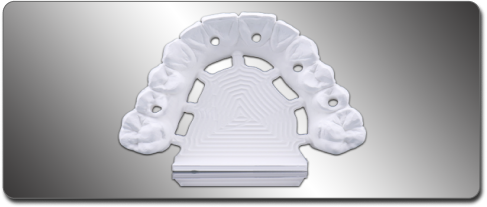

At the heart of our

At the heart of our  Beyond the unsurpassed quality restorations provided by Versamill machining Centers and other products associated with our

Beyond the unsurpassed quality restorations provided by Versamill machining Centers and other products associated with our