Versamills Are the Beginning Different—Much More than an ARUM

Arum-based Versamill precision dental machining centers

are decidedly different than the standard Arum machines delivered by other distributors. Before they reach your door, each Versamill goes through our own 54-point inspection process and is performance tuned by our team of machine tool experts, a process that includes installation of our exclusive enhancements specifically designed to increase performance, durability, and reliability.Arum Dental Milling Machines

to the North and South American markets. It is this unrivaled experience and dedicated resource that has enabled us to identify key areas of Arum machine design that we could adopt in our Versamill products that save you thousands of dollars annually in terms of production up-time, machine cycle time (50-70% less time than the nearest competitor), reduced bench time, eliminated re-work, and more.

Just the Beginning

True, our Arum-based Versamill precision dental machining centers differ significantly from the standard Arum machines delivered by other distributors.

Each Versamill is performance tuned by our team of machine tool and CAD/CAM experts and includes exclusive enhancements specifically designed to increase performance, durability, and reliability.

Here are a few of our enhancements that are only available through Axsys Dental Solutions:

- Modifications to axes drive system to provide smoother, faster machine motion.

- Custom coolant delivery system to increase durability and coolant delivery to the cutting surfaces.

- Numerous modifications to improve interface and operational performance.

- Upgraded spindle drive system providing increased spindle power & torque.

- Modifications to tool change cycle resulting in an approximate 50% reduction in chip-to-chip tool change operations

- Modification to machine control parameters to improve interface and operational performance.

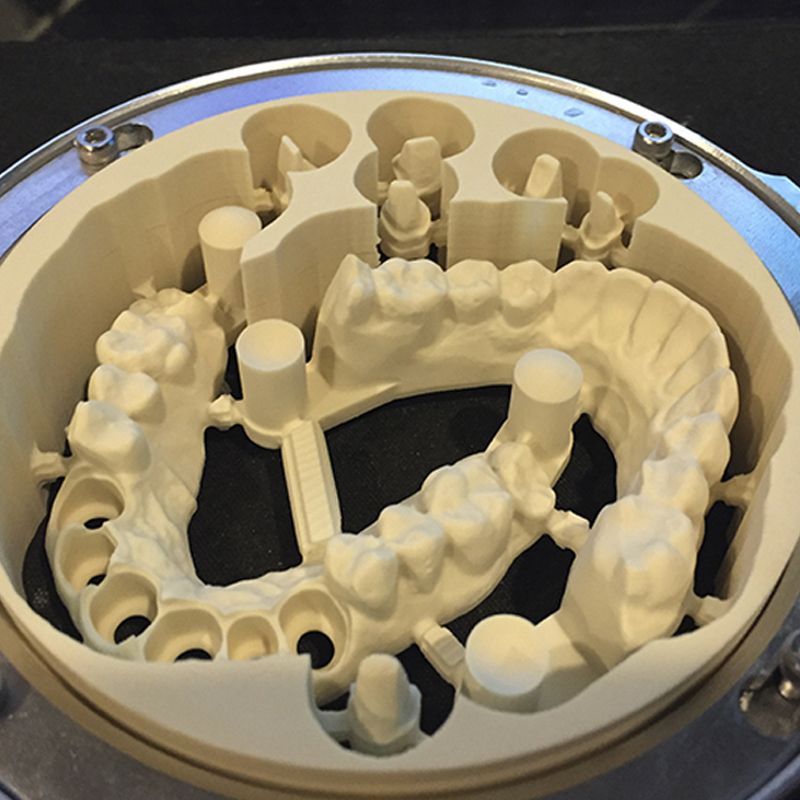

- Specially designed and manufactured stainless steel lithium disilicate and Titanium Pre-form holding fixtures that provide significantly increased durability, accuracy and repeatability.

- Custom CAM machining template providing greater flexibility, superior surface finishes and gingival margin integrity with faster machine cycle times.

- Custom libraries providing greater flexibility and significantly more aesthetic emergence profiles.

- And even more...

With over 800 man-years experience in digital manufacturing, our extensive experience and knowledge in CAD/CAM software development, sales, marketing, support, training, and distribution—along with the same experience and knowledge in CNC machine tool technology—puts us in a unique position in the market—the position of leadership. We can:

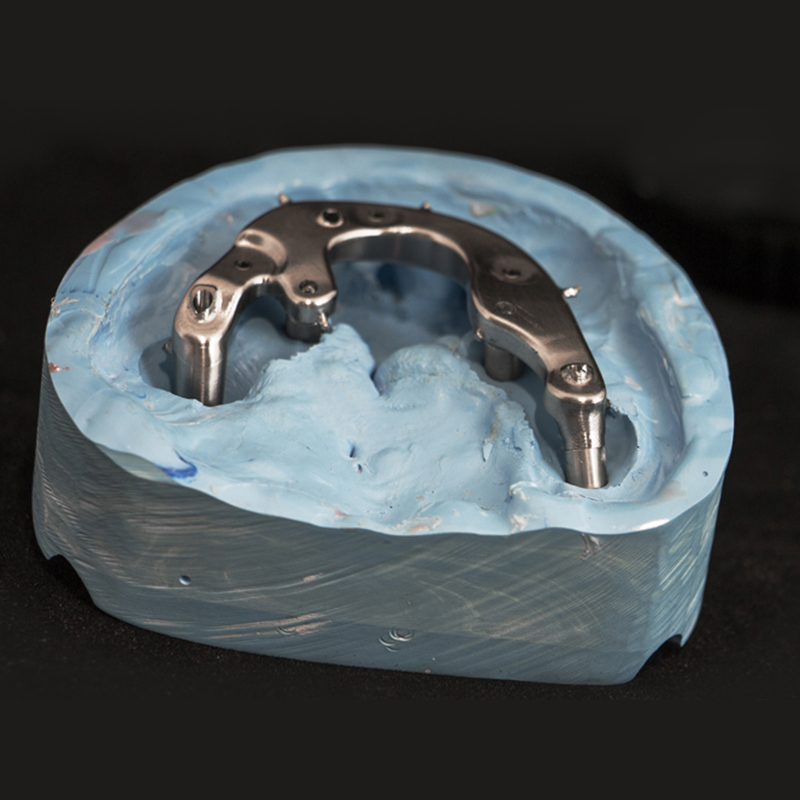

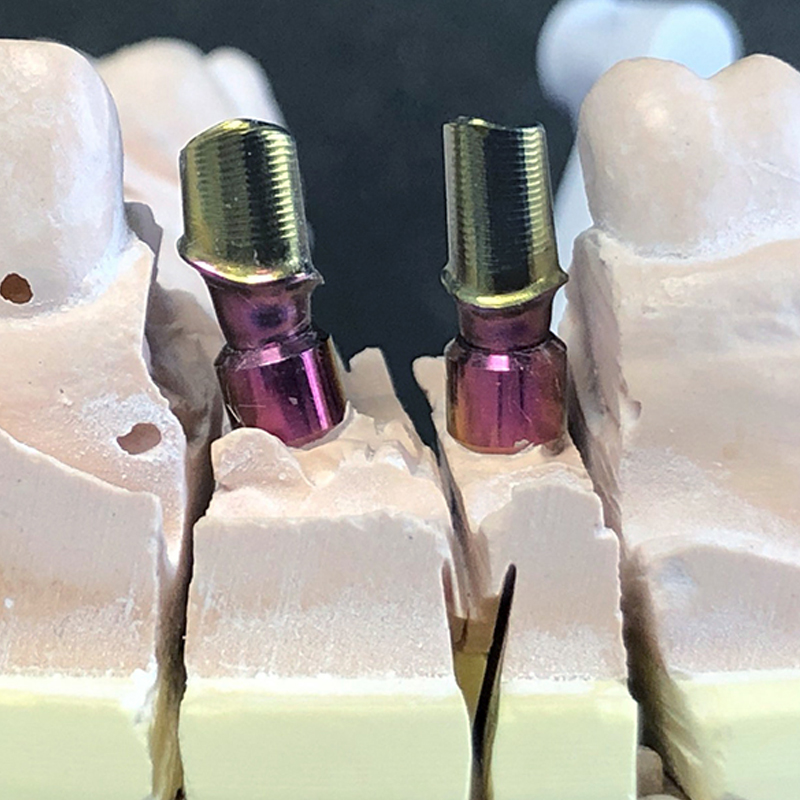

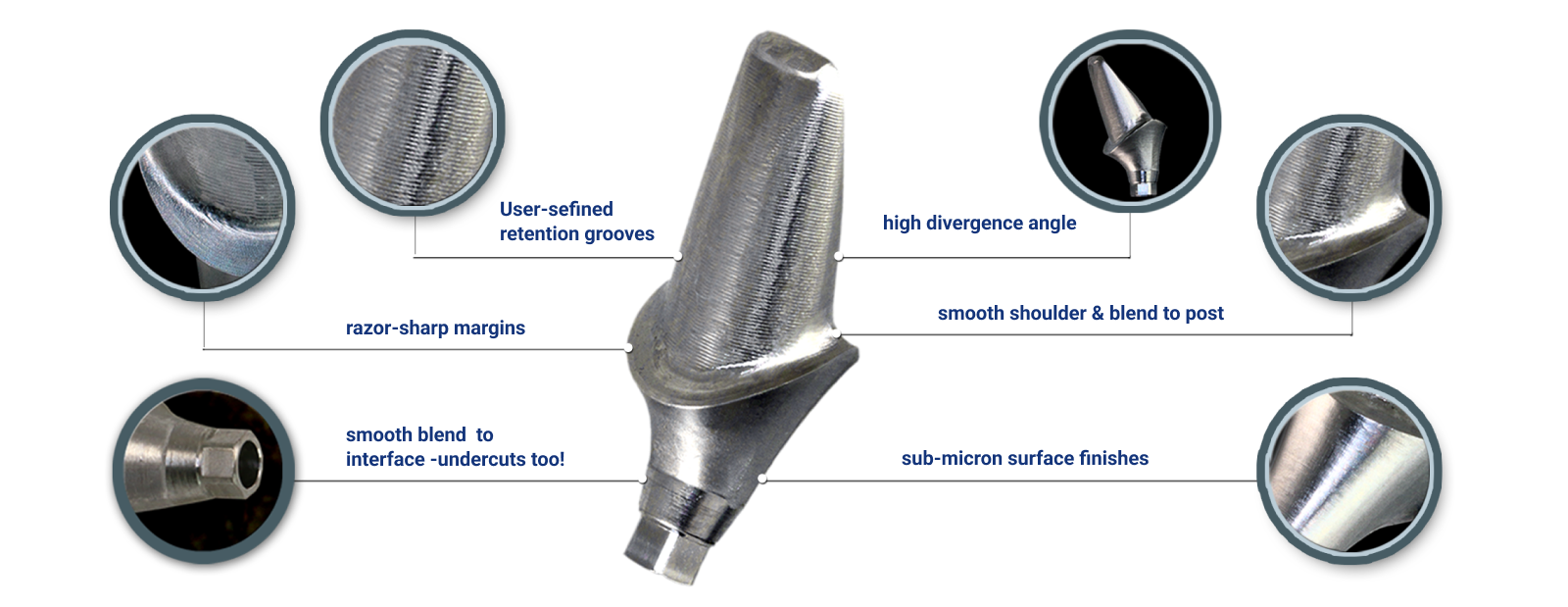

Custom Abutment Machining Solution

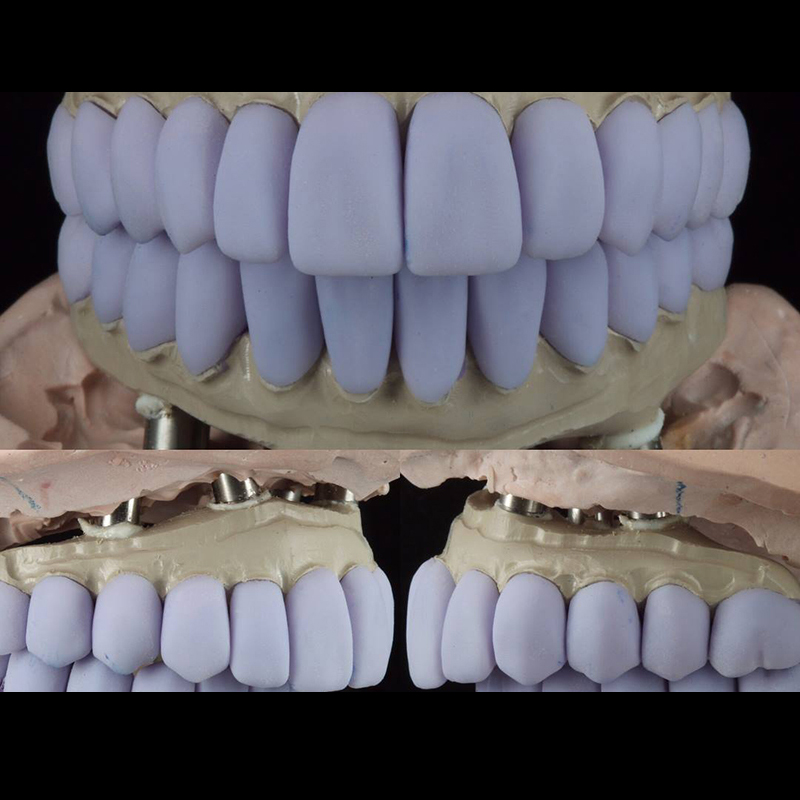

Leveraging our decades of manufacturing experience and Versamill Quality to produce off-the-machine quality that has to be seen to believe

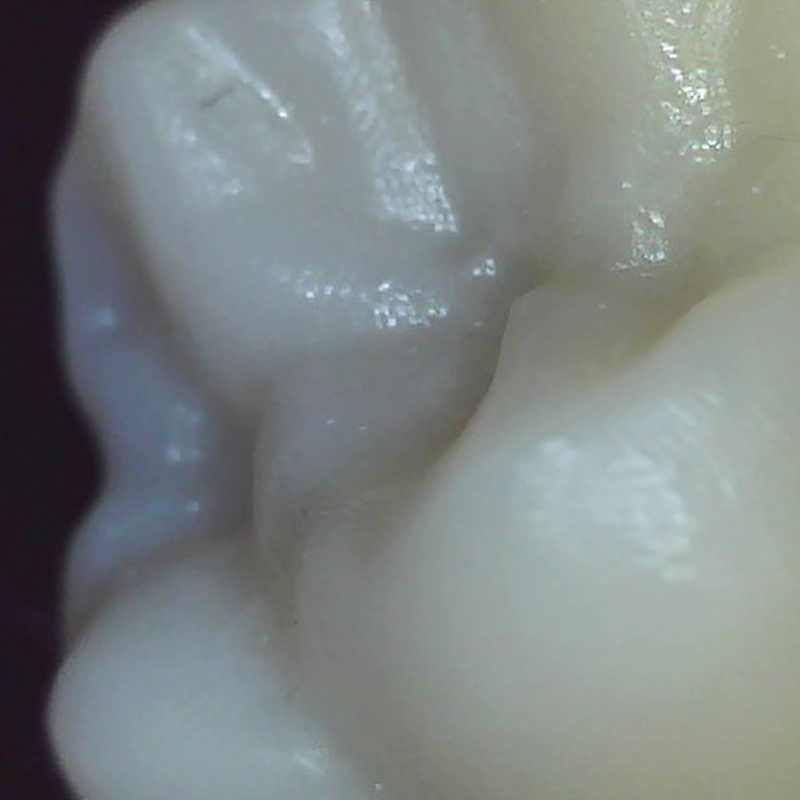

Zirconia Machining Solution

Leveraging our decades of manufacturing experience and Versamill Quality to

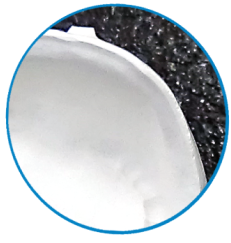

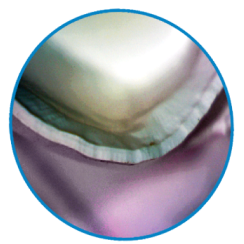

Produce off-the-machine quality that has to be seen to believe. Our soft material crowns are produced with high occlusal detail and with thin, clean margins without the heavy margin reinforcement typical of competitive solutions

Gingival Margin Integrity

The margin is the most susceptible to damage during the milling process. To maintain the margin’s integrity, additional thickness is added to the margin in software to strengthen it during milling and provide extra stock in case of a violation during the milling process.

The margin reinforcement feature, which can be as much as 200µm in inferior systems, is helpful during milling but must be manually removed as part of the margin-finishing process. The primary causes of these violations and the need for margin reinforcement include:

- Machine rigidity.

- Machine spindle performance including; internal structural quality, excessive cutting tool run-out, tool deformation etc.)

- Fixture rigidity including lack of quality machine rotary axis gear reducers.

- Lack of available robust machine strategies

- Poor output generated from within the CAM software.

- Improper toolpath “processing” from within automated CAM software templates.

- Combination of all the above

Latest Works

Below are a few examples of our clients’ work; more can be found by visiting our Portfolio Page.