Custom Implant Abutment Solution

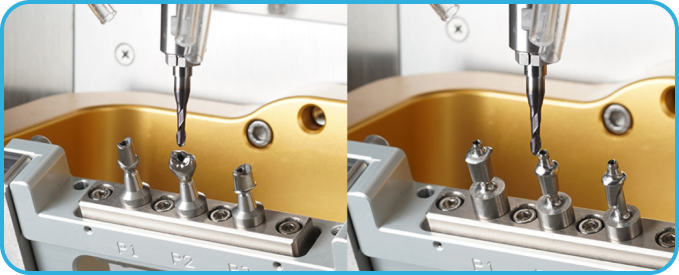

Using the Axsys Dental Solutions Custom Abutment Manufacturing System, you can increase your profits by up to 300% while eliminating the need to outsource your implant abutment business. Our Versamill Precision Dental Machining Centers’ accuracy and durability are boosted by automated, highly effective multi-axis machining templates designed by our skilled team of application engineers. Make your own custom abutments quickly and in-house, so you can match your aesthetic while maintaining complete control over design and delivery.

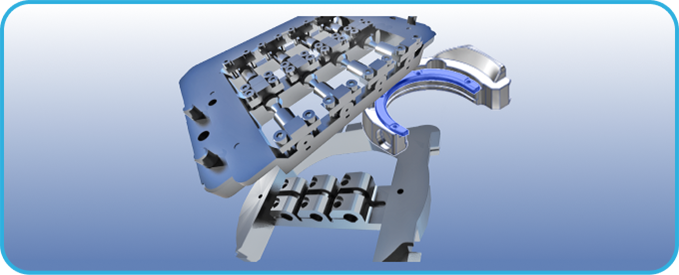

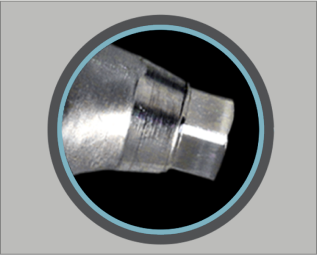

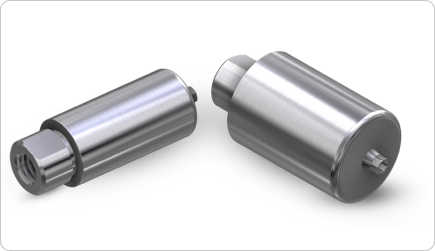

Our Versamill customized abutment fixtures are of exceptional quality and offer solutions for the majority of premill manufacturers. Our in-house fixtures ensured that the premill blanks were properly aligned within the fixture prior to milling, while also significantly increasing manufacturer and platform compatibility. This makes it easier to ensure that your custom design and the platform’s interface are completely compatible. To avoid any potential deformation that could jeopardize fit and long-term durability, our fixtures and automated multi-axis milling templates also protect the critical interface from dynamic loads applied during the blank milling process.

Compared to the OEM’s standard product, the most recent version of our abutment cartridge for Versamill Precision Dental Machining Centers offers numerous advantages and improvements.

Our abutment manufacturing system uses the same base fixture as zirconia cartridges. This time- and money-saving approach, combined with the Versamill’s dual coolant tank swapping capability, makes the transition between machining titanium abutment blanks and zirconia easier than ever.

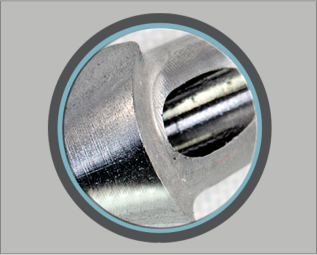

The abutment cartridge fits directly into the standard Versamill base fixture, eliminating the need for technicians to go through a complex and time-consuming calibration process. Because your machine undergoes a final milling operation during installation, the base fixture is customized at the machine level to eliminate even the smallest inaccuracies and ensure a repeatable, mechanical fit.

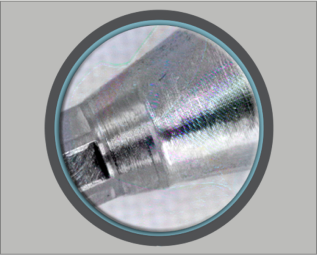

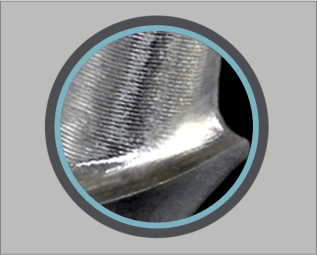

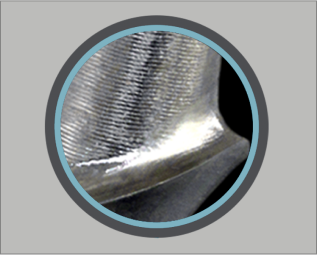

Versamilll fixtures allow vertical milling of a custom abutment’s subgingival or occlusal areas, as well as milling retention grooves in a single top and bottom side-milling operation.

- Highly accurate one piece design eliminates stack tolerance errors

- Cartridge is finished machined directly on each mill ensuring positional accuracy without complicated setup.

- Fully compatible with NT-Trading abutment inserts, analogs, and blanks.

- Alignment pins ensure repeatable accuracy.

- Sub-30 Micron repeatability possible.

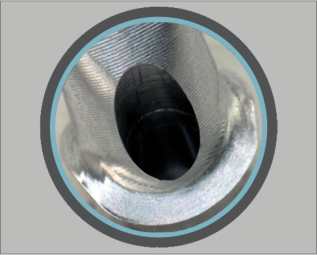

- Blank is fully supported by both the analog and tailstock greatly improving rigidity and surface finish.

- Tailstock is designed so that any rotational forces induced during milling are NOT applied directly to the interface.

- Modular design allows labs and milling centers to mix and match different size abutments and platforms in a single setup.

We provide the most fixtures for our Versamill dental mills, including premill blanks, Cerec or PrograMILL blocks, C-Clamps, and others. We can provide an OEM or custom-designed and manufactured fixture to meet your specifications. We currently support industry leaders including DESS, Straumann, Medentika, Open Implants, Dentaswiss, Preat, NT Trading, Arum, and others.

Superior Abutment Manufacturing Capability

Automated Machining of Even the Most Severe Abutment Designs

With over 40 years of digital design and manufacturing experience, we can provide the most comprehensive custom abutment machining solution, accommodating a wide range of design features and abutment characteristics.

Combining Axsys expertise with the quality and precision of Versamill machine technology yields superior restoration:

- Finest of restorative margins.

- Most esthetic emergence profiles.

- Perfect fits.

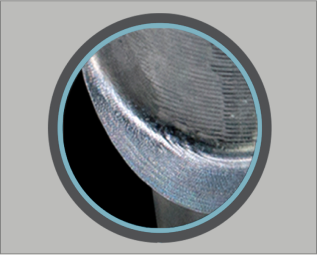

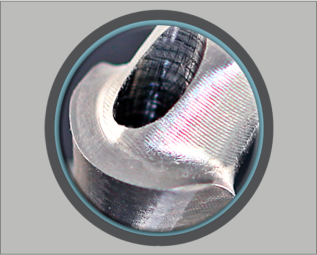

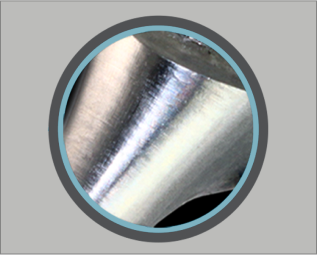

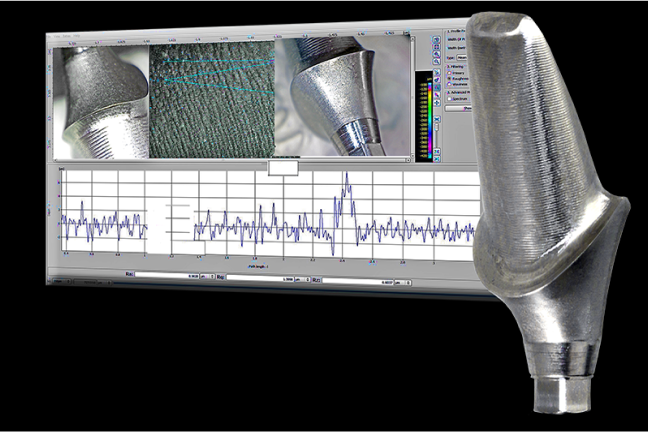

- Smoothest subgingival surface finishes (under 1µm).

- Completeness of final machined product.

- Minimum post-machining hand-work.

The Versamill high-speed probing system replaces the standard Arum-based probing system. This system includes a replacement probe and automatic probing routines.

Implementing this system saves tens of thousands of dollars by reducing probing routines from hours to seconds.

Robust Milling Templates to Process Even the Most Complex Cases

- Extreme Subgingival Radius.

- Near Vertical Supragingival "Flange".

- Occlusal Undercut.

- Large Divergence Angle.

- Extreme Depth Requires Special Rough & Finish Machining Considerations.

- Supragingival Machining Challenge.

- Subgingival Undercuts.

- Large "Clocking" Channel.

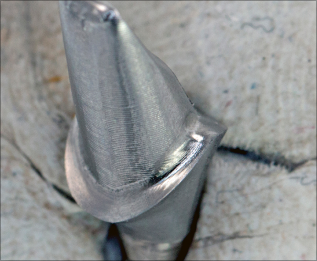

The Laser Interferometer surface finish test image shows a 0.9µm Ra finish.

Ra is the arithmetic average deviation of surface valleys and peaks, which is used to describe the roughness of a machined surface.

Custom Abutment Machining with an NT-Trading NT-Preform Blank on the Versamill 5X200 Precision Dental Machining Center.

Implant Supported Restorations from

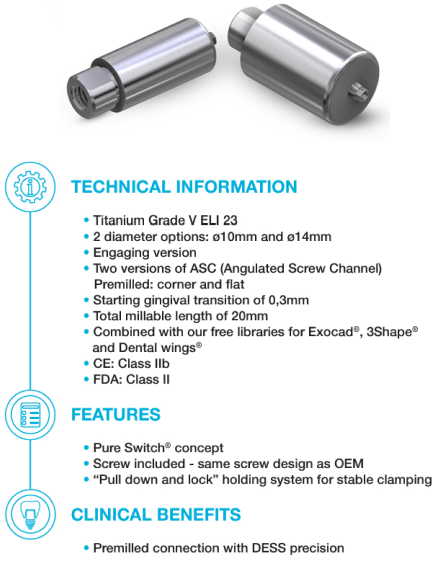

with repeatable precision and superior engagement

DESS Pre-milled Blanks are available in Titanium Grade 5 ELI (extra low interstitial) in 10 and 14mm diameter and Micromelt CrCo 14mm diameter. The Micro Melt Cobalt-Chrome alloy has no internal tension, so however radical your design is, the final custom abutment will preserve the shape along the process resulting in a lower probability of ceramic cracks.

DESS Pre-milled blank is an excellent choice for your digital projects, with a full assortment of Titanium Grade V ELI (extra low interstitial) and the exclusive Micro Melt Cobalt-Chrome.

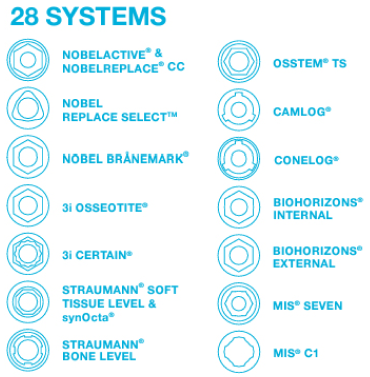

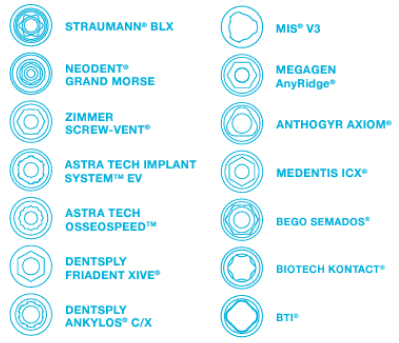

- Available in 32 compatibilities.

- Available in Titanium 10mm and 14mm diameter with 20mm millable length.

- Available in CoCr 14mm diameter with 20mm millable length.

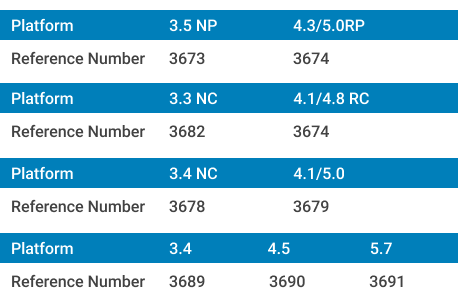

DESS Ti Bases provide a new interface line designated to provide security and adjustment, without increasing the cost of the prosthesis. Ti Bases help save time when working on the most sensitive part of the prosthesis, the adjustment with the implant.

The DESS Ti Base measurements and design ensures a stable union, reinforcing the structure of zirconium in the areas of greatest stress, softening edges and ensuring the service life of the prosthesis.

The SelectGrip® surface provides greater adhesion of the structure with the cement. Ti Base models are available for most of the implant connections in diameters NP, RP and WP for both, single tooth prosthesis (engaging) and multiple teeth prosthesis, dental bridges and hybrids (non-engaging).

DESS titanium bases support Exocad®, 3Shape®, Dental Wings®, and Blenderfordental®, enabling seamless digital dentistry integration.

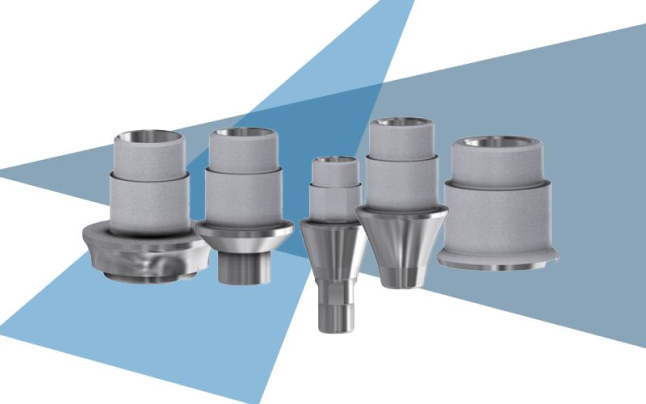

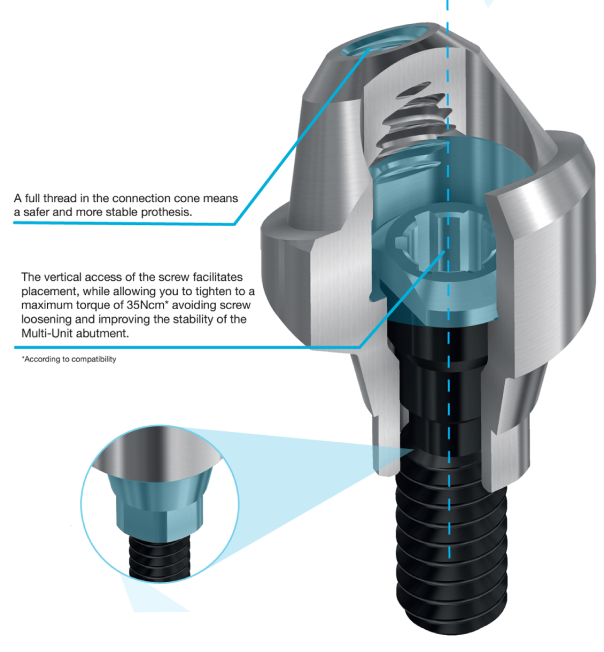

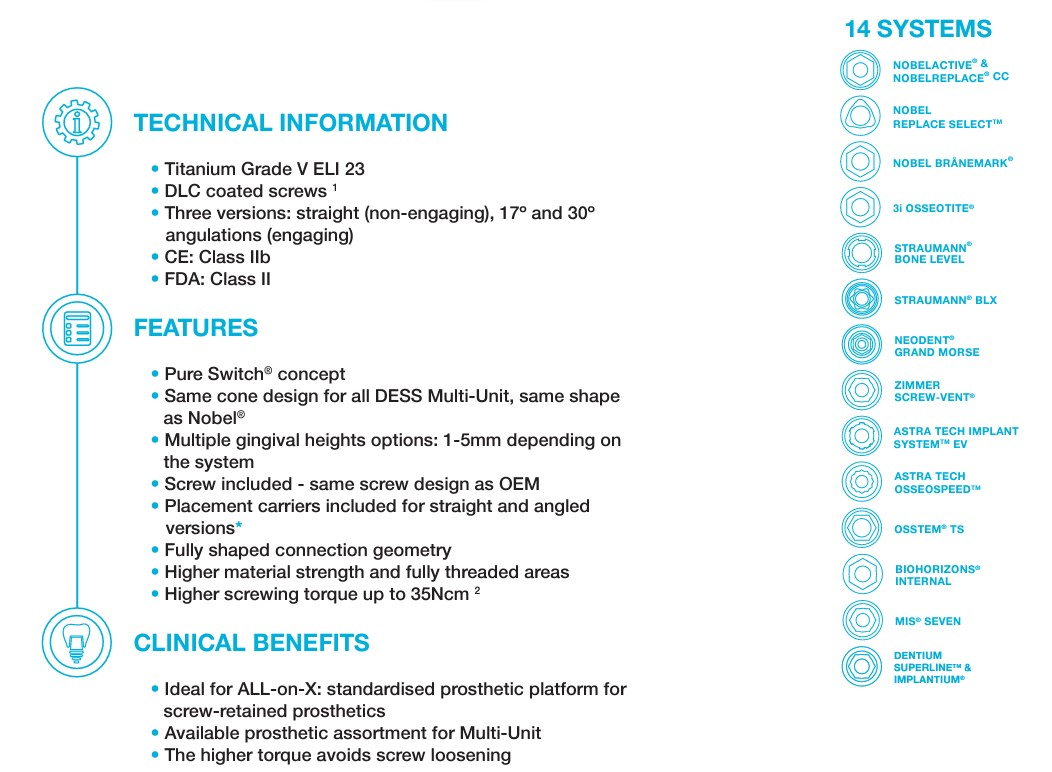

DESS ® Multiunit abutments are available in many connections. Compatible with the major brands existing in the market. They allow the height level to be raised and transform the connection to meet the needs of special clinical cases.

They are available in straight and angled (17º and 30º) versions, engaging and non-engaging, from 1 to 5mm collar height depending on the implant system. All of them are made with the Titanium Grade 5 ELI and some come with DLC coated screw.

The DESS Free Multiunit ® and Dess Uniabutment ® libraries allow the design of multiple screw retained restorations in most of the CAD/CAM systems.

DESS offers the most comprehensive range of Multi-unit abutments, which are perfect for partial and full arch restorations. Available in Straight version, non-engaging and Angled version engaging.

- Available in 14 compatibilities.

- Available in 5 different gingival heights.

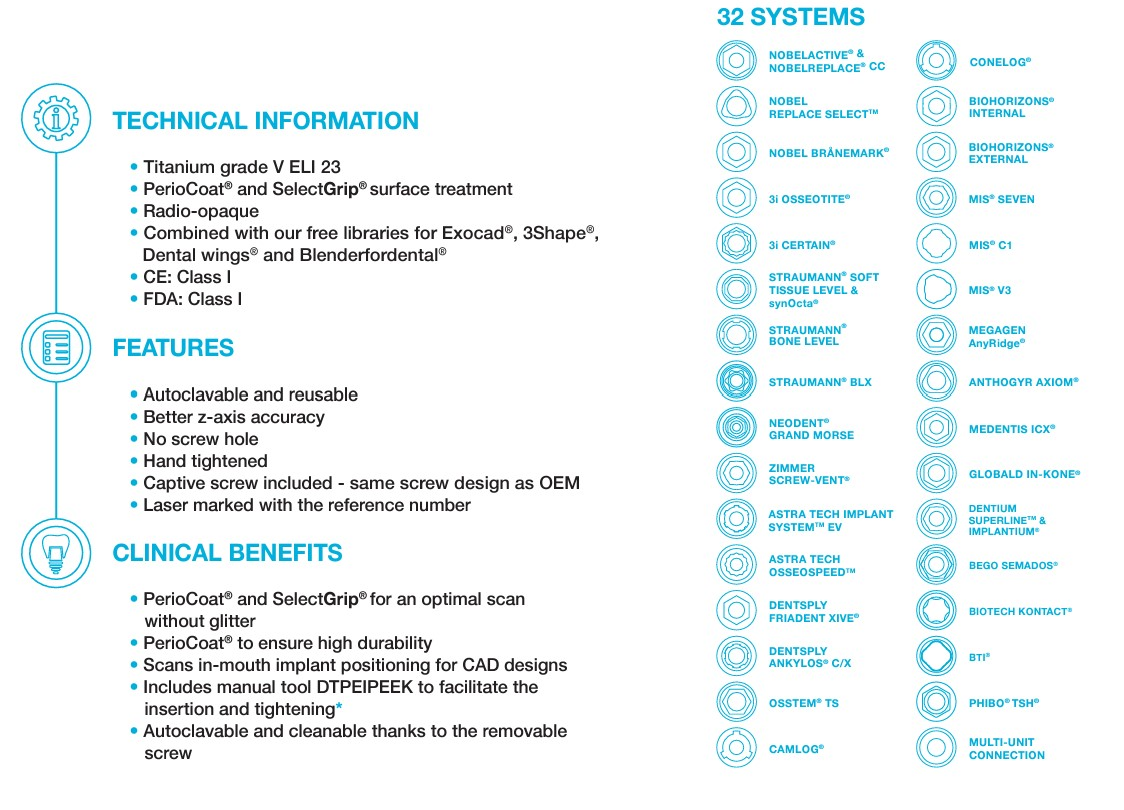

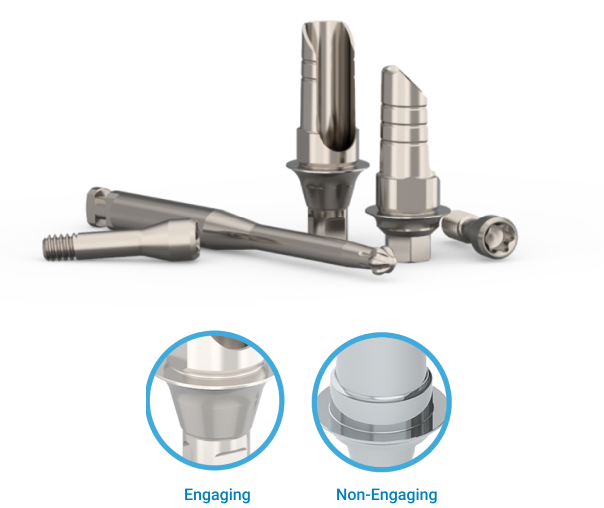

This scan body is made of titanium that includes ZrN coating to reduce glitter effects and is designed for both intraoral and desktop scanning.

It has a fixed internal screw for hand tightened.

This scan body comes with the Manual Tool for Intraoral Scan abutment, DTPEIPEEK-P2, is made of PEEK and helps as a carrier to position the intraoral scan abutment on an implant.

DESS Intra Oral Scan Bodies are 100% PEEK with no reflective surface or glare.

Titanium and PEEK with titanium connection surfaces become reflective, creating glare and distortion over time.

By using only PEEK we ensure an accurate distortion free scan every time.

The product is extremely strong and reusable due to the strength and long term durability of PEEK which has been used in the medical and dental profession for years. All other intra oral scan bodies have a screw access hole at the top which results in inaccurate scans because there is greater Z axis distortion. DESS scan bodies have a low profile. At only 10mm in total length from the implant connection and is 4mm in diameter. Size allows easier use in the posterior.

Available for single and multiunit cases where accuracy is paramount.

DESS® presents a line of Analogs made of stainless steel AISI 303.

The Analogs have a head that reproduces the implant system joint and have a gentle retaining area to easily position the soft gum in the working model.

All DESS® Analogs have an effective circuit and self-locking cross retainers that, inside the plaster, provide extraordinary embedding even in cases of abutment drilling on model.

The discrete size can be easily fitted, despite the implants being close together or not parallel.

DESS specially designed 3D Analogue comes with a hex screw to guarantee that the analogue is positioned at the bottom of the model

— Available in 32 compatibilities.

Implant Supported Restorations from

Lifetime Component Warrnty

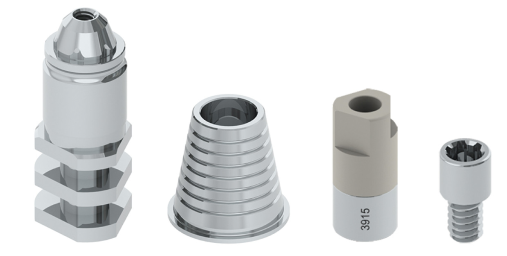

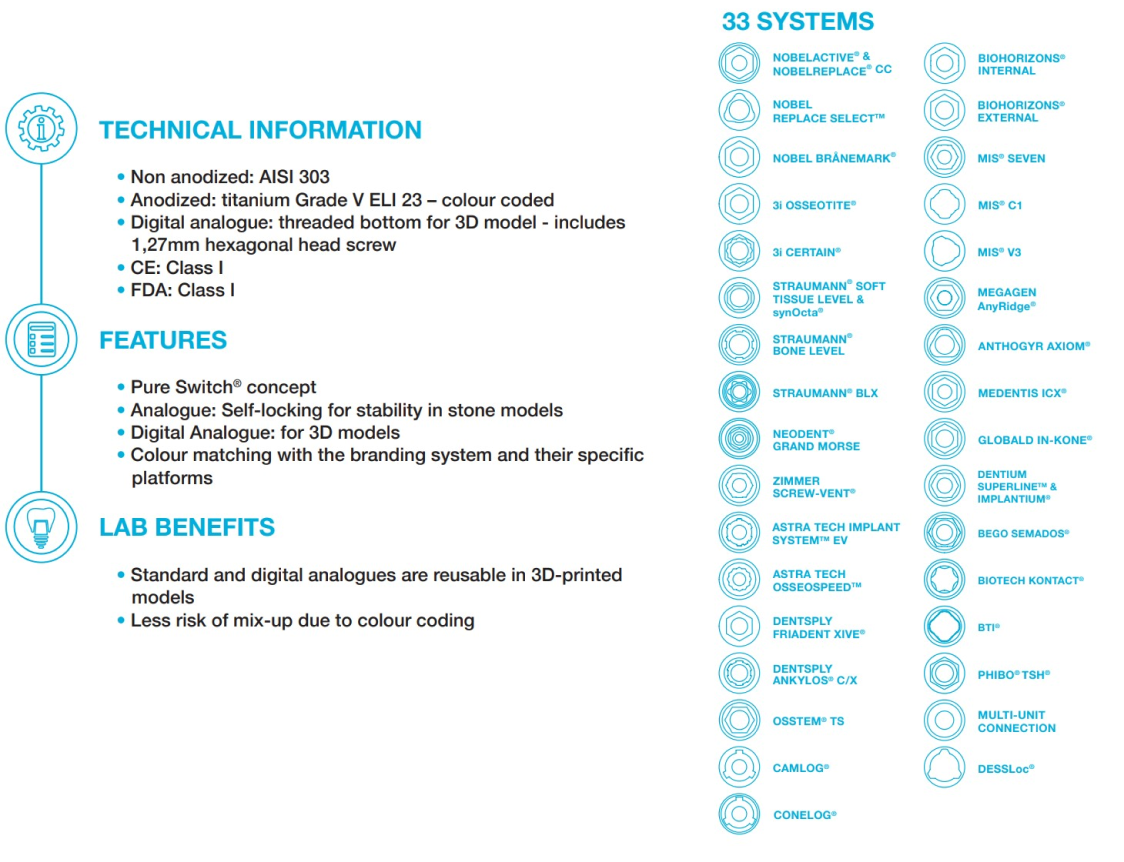

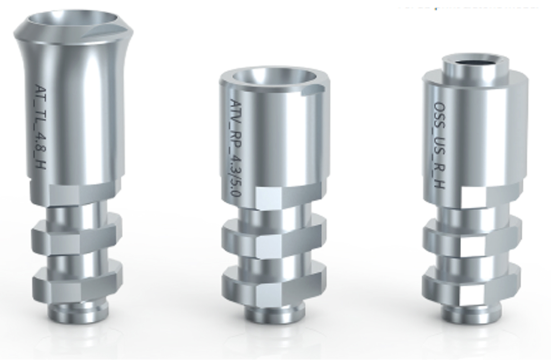

Open Implant®-Premill

- For cases with unique anatomical considerations or irregularities

- For achieving optimal esthetic results in anterior tooth restorations

- When a customized emergence profile is necessary

- Libraries available for 3Shape and exocad

- Available for both iMes iCore and Versa 5x milling machines

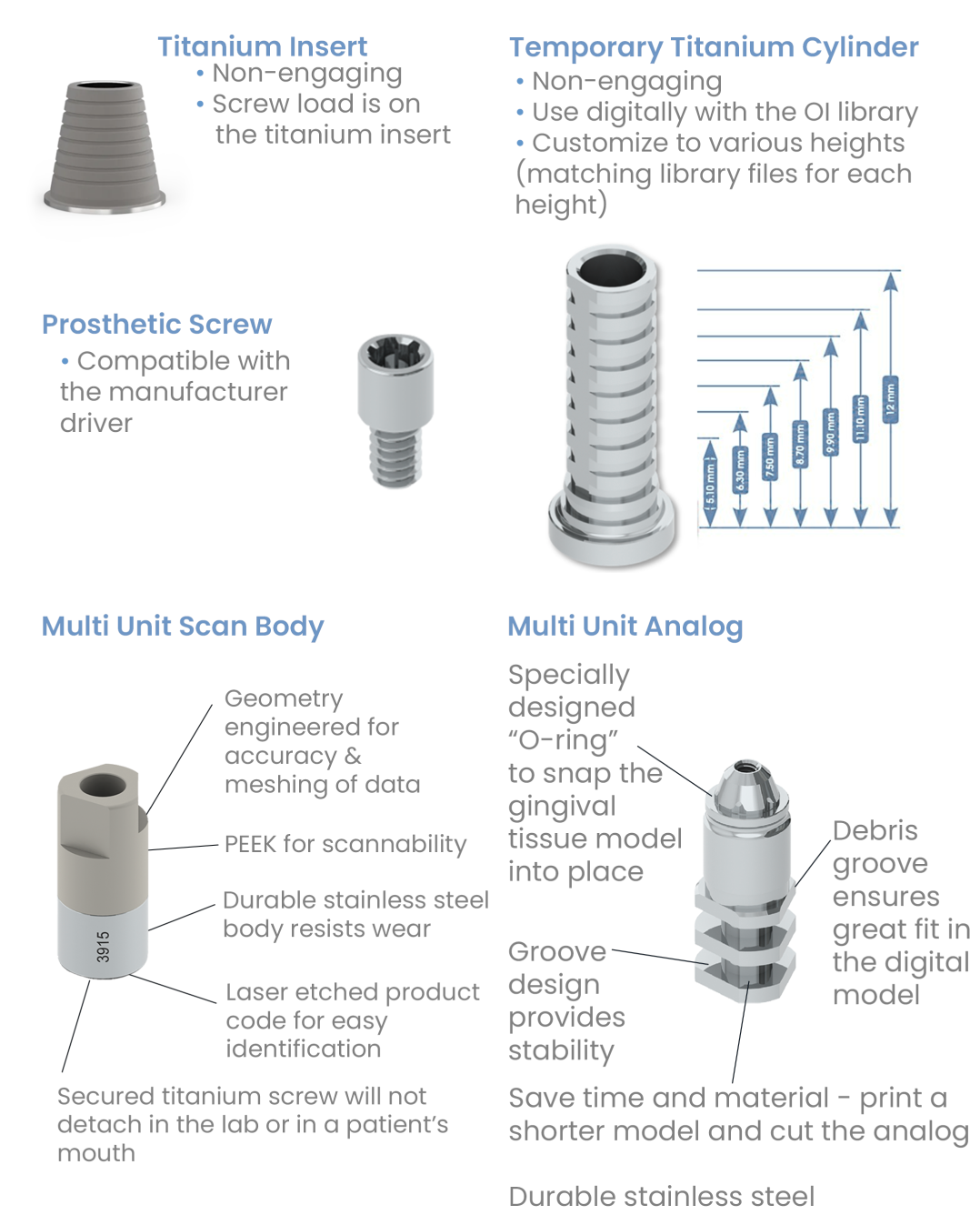

- Screws are compatible with platform respective OEM drivers

- Screw(s) included

- Customize the height of the Ti-base up to 8 or 10 mm

- Gingival height options for various patient situations

- For a streamlined workflow—use with scan bodies and library files for each height

- Engaging flat to ensure anti-rotation

- Cement groove for excess cement

- Set includes one screw

- Screw is compatible with implant manufacturer driver

- 4 custom chimney height options up to 8mm

- Angulation up to 30°

- Gingival height options for various patient situations

- Engaging flat to ensure anti-rotation

- Cement groove for excess cement

- Driver designed to work with our entire range of ASC platforms

- Set includes one screw

Implant Supported Restorations

Arum Dentistry

Review the products

ARUM-PREFORM®

- Precision prefabricated implant interface.

- Available in 10.0mm and 14.0mm diameters.

- High precision with 5 micron tolerances.

- Highly esthetic emergence profiles

- Includes both millling and clinical screws

- Primary telescopes on implants.

- Mesio-structures for crowns and bridges.

- Occlusal screwable structures.

ARUM presents a complete line of Ti-bases designed to provide security and adjustment, without increasing the cost of the prosthesis.

Additional savings are realized as less time is requiured to work on the most sensitive part of the prosthesis—the adjustment with the implant.

Designed specifically to ensure a stable union, reinforcing the structure of zirconium in the areas of greatest stress, softened edges and extended service life of the prosthesis.

- Titanium interface abutment

- 2 Screws included (Angled screw / Straight screw)

- Precision machined up to ± 5µm

- Superior level of biocompatibility

Approved by FDA, CE, ISO 9001, ISO 13485

- Self – centering conical connection.

- Maximum flexibility of divergent implant positions.

- 2 Screws included (Angled screw / Straight screw)

- Precision machined up to ± 5µm

- Superior level of biocompatibility

- Exterior retentions for more cementation bonding

- Bars.

- Bridges.

- Non-engaging structures.

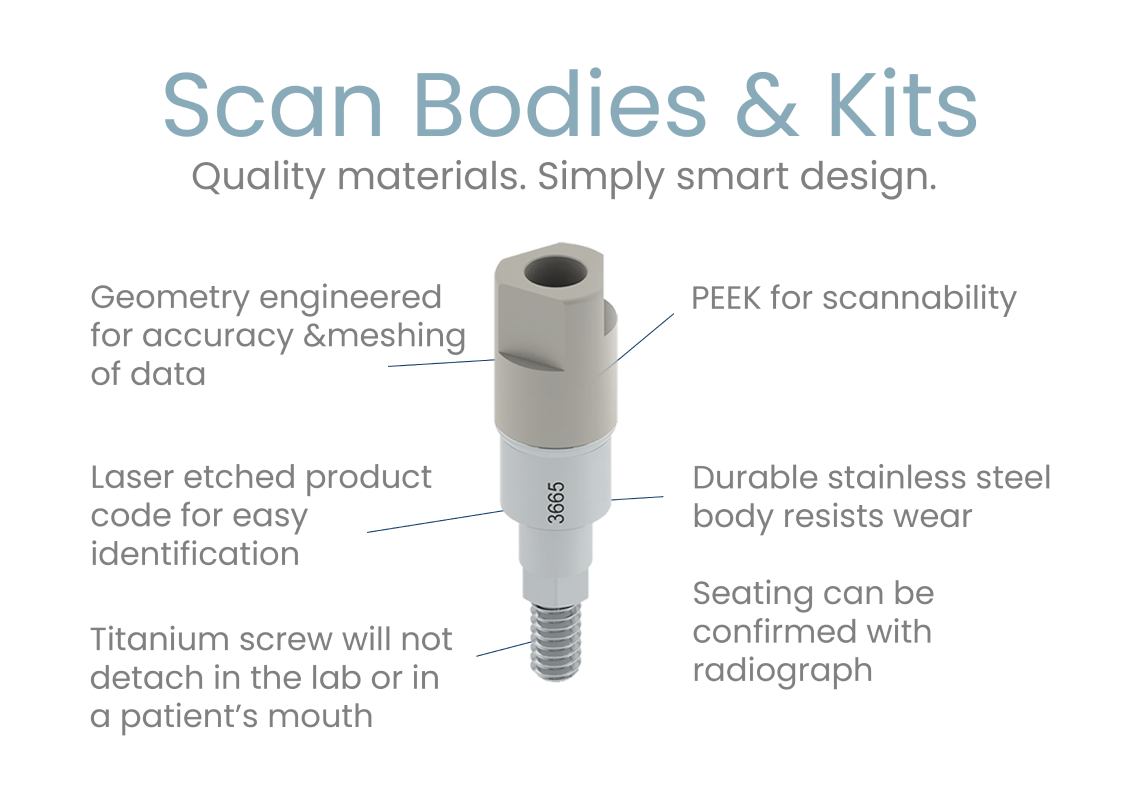

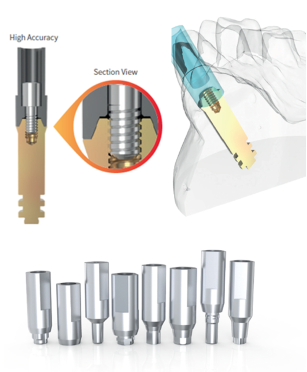

ARUM scanbodies represent the position and orientation of the respective dental implant or analog in the CAD/CAM scanning process. This helps the CAD/CAM software to correctly align the subsequent CAD/CAM restorations.

ARUM scanbody ensures that it is optimised for a wide range of optical scanners.

- High accuracy

- Free remote library setup

- More than 500 implant connections

- Different shape geometry ensures a perfect transfer in CAD software in case of incomplete scanning detection.

The Arum intraoral scanbody is specifically designed with an internal spinal thread, which prevents detachment and loss of screw once it is tightened and fully engaged to the implant fixture

The lower body of the intra-oral scanbody is concave shaped. This minimizes pressure on the patient’s gum during setting of the scanbody, thereby reducing experienced pain and securing a broader gingival area for future implant placement.

The holder allows the dentist to quickly and easily set the intra-oral scanbody into the implant fixture. This is especially effective for challenging cases such as the most distal molar.

The “A” Line of the ARUM intra-oral scanbody provides an indicator to the operator to check for a complete connection to the implant fixture and thereby ensuring a more precise prosthesis.

- Fixture Connection Indicator on scanbody – A-line

- Inner Thread for Screw Holding

- Concave Neck Design

- Autoclavable

- Scanbody Holder included

- Implant analog for digital model manufacturing.

- Anti-rotational design.

- Precision machined up to ± 5μ

- Positional adjustment possible.

- Analog design supports precise repositioning of removable gingiva mask.

Digital Implant Technology

High-quality FDA Cleared Products for Implant Supported Restorations- Precise prefabricated implant interface.

- Available in two different gingiva heights.

- Individual abutment design by prosthetical terms.

- Optimal interface protection by bilateral fixing in preform holder during the milling process.

- Primary telescopes on implants.

- Mesio-structures for crowns and bridges.

- Occlusal screwable structures.

For implant supported individual hybrid abutments.

- Engaged unit.

- For individual abutment designs.

- Large glue surface providing durable solid connection to the base.

- For conventional use as well as for use in the CAD/CAM process.

- Self – centering conical connection.

- Maximum flexibility of divergent implant positions.

- Stressless fitting by optional adhesive connection (female part).

- Female part compatible between the different implant systems and diameters.

- Force application caused by tube shape and integrated screw (Straight Abutment) or mounted screw (Angled Abutment).

- Bars.

- Bridges.

- Non-engaging structures.

Scanbody for high-precision implant position transfer.

- Exact positioning by metal interface.

- Conceived for intra-oral scanners.

- Screw integrated.

- X-ray detectable.

- Rotatable to facilitate interproximal crowding. Different shape geometry ensures a perfect transfer in CAD software in case of incomplete scanning detection.

- Scanbody for model scanning.

- Scanbody for inter-oral scanning.

- Non-engaging structures.

- Implant analog for digital model manufacturing in the model builder library.

- Two-piece repositionable implant analog.

- Precise positioning.

- Positional adjustment possible.

- Analog design supports precise repositioning of removable gingiva mask.

- For model manufacturing in digital workflow.

- Scanbody for inter-oral scanning.

- Non-engaging structures.

Titanium Grade 5 ELI.