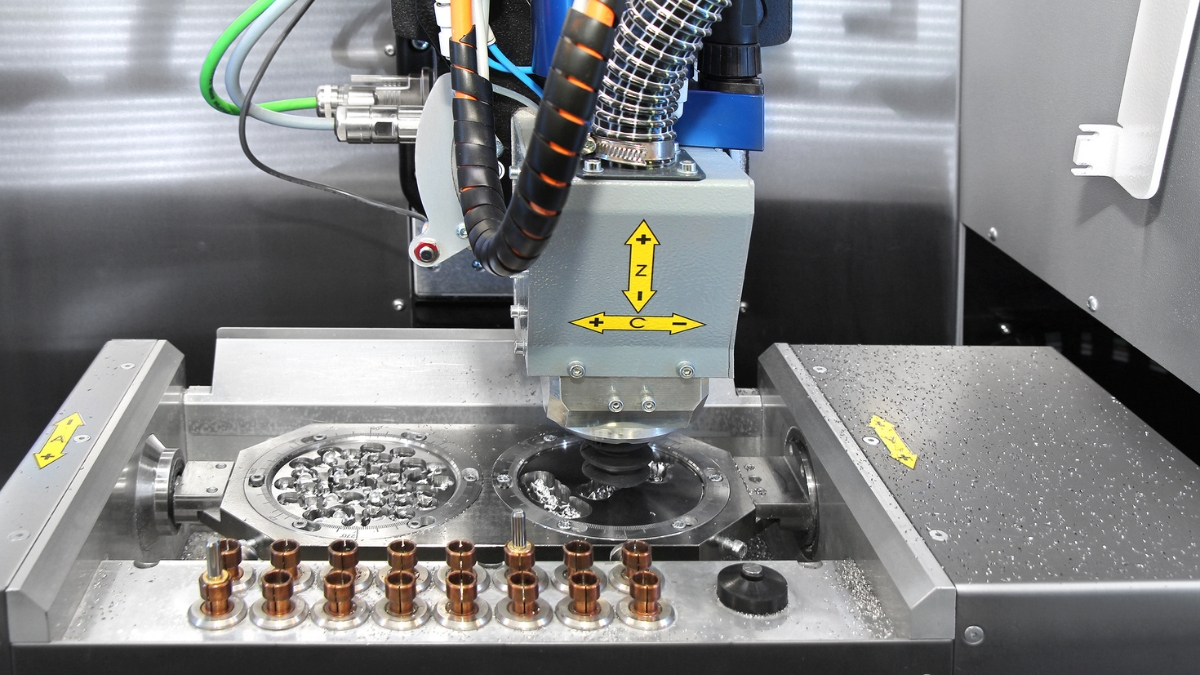

The landscape of dental restoration has been revolutionized by the advent of Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) technology. At the heart of this digital revolution lies the CNC milling machine, a cornerstone in modern dental laboratories.

Understanding Your Needs: The Foundation of Machine Selection

Before diving into the technical specifications of various milling machines, it’s crucial to thoroughly assess your lab’s specific needs. This involves a careful evaluation of several key aspects:

- Materials: What materials will you be milling? Different machines are optimized for different materials, such as zirconia, porcelain, wax, PMMA, composite, and metals. Consider the range of restorations you offer or plan to offer in the future.

- Restoration Types: The types of restorations you produce will influence the required precision and axis movement of the milling machine. Crowns, bridges, inlays, onlays, implants, dentures, and surgical guides each have unique requirements.

- Production Volume: How many units do you mill daily or weekly? Production volume is a crucial factor in determining the speed and throughput you need. A high-volume lab will require a machine with faster milling speeds and potentially automated features like tool changers.

- Workflow Integration: How will the milling machine integrate with your existing CAD/CAM system? Seamless integration is essential for a smooth and efficient workflow. Ensure compatibility between your design software, CAM software, and the chosen milling machine.

- Budget: CNC milling machines represent a significant investment. Establish a realistic budget that considers not only the initial purchase price but also ongoing maintenance costs, consumables (like burs), and potential upgrades.

- Space Requirements: Milling machines vary in size and footprint. Assess your lab’s available space and ensure the chosen machine can be comfortably accommodated.

Call Axsys Dental Solutions at (855) 687 7941 today for more information!

Key Features and Specifications to Consider:

- Axis Movement: Milling machines typically operate with 3, 4, or 5 axes. More axes allow for more complex and intricate restorations, reducing the need for manual adjustments and improving accuracy.

- Milling Speed: Milling speed is a crucial factor for high-volume labs. Look for machines with high spindle speeds and efficient material removal rates.

- Precision and Accuracy: Accuracy is paramount in dental restorations. Look for machines with high precision and minimal deviation.

- Tool Changer: An automatic tool changer allows the machine to switch between different burs automatically, reducing manual intervention and increasing efficiency.

- Material Compatibility: As mentioned earlier, ensure the machine is compatible with the materials you intend to mill.

- Software Integration: Seamless integration with your existing CAD/CAM software is crucial for a streamlined workflow. Ensure compatibility and look for features like automatic tool path generation and collision avoidance.

- User Interface: A user-friendly interface simplifies operation and reduces the learning curve. Look for machines with intuitive software and clear instructions.

- Maintenance and Support: Consider the availability of technical support, maintenance services, and spare parts.

Choosing the Right Machine for Your Lab:

The ideal CNC milling machine for your lab will depend on a combination of the factors discussed above. There is no one-size-fits-all solution. Here’s a general guideline:

- Small Labs/Low Volume: A 3 or 4-axis machine with good material compatibility and a reasonable price point might be sufficient.

- Medium Labs/Medium Volume: A 4 or 5-axis machine with faster milling speeds and a tool changer can improve efficiency.

- Large Labs/High Volume: A 5-axis machine with high speed, high precision, and automation features is essential for maximizing throughput.

Did you know?

The accuracy of a CNC milling machine is not solely dependent on the machine itself. Factors like proper calibration, tool selection, material preparation, and environmental conditions also play a significant role.

Call Axsys Dental Solutions at (855) 687 7941 today for expert guidance and tailored solutions to meet your dental lab’s milling needs.