3D Dental Printers from Phrozen

Phrozen is a 3D printer company that is developed by engineers based in Taiwan whose major development focus is on DLP-based and LCD-based resin 3D printers.

The focus on this 3D printing technology is due to the fact that this technology can save users printing time and at the same time replicate their designs with ultra-fine detail.

Excellent mechanical design, dedicated RD work in optical engines, aluminum-CNC parts, and the use of high-quality components (linear rails, ball screws, and ball bearings) are key elements of Phrozen 3D printers. Moreover, Phrozen printers are based on an open platform that allows for the use of 3rd-party printing materials.

You can choose whatever resin you prefer to use with your Phrozen printer. That’s Phrozen, a high-quality, cost-effective, and open-minded 3D printer company.

Phrozen focuses on functionality and features the best Z-stage in its class with its proprietary ParaLED optical engine. Resulting in the best large format 3D printer in its class.

In optical systems for resin 3D printers, light intensity, wavelength, and optical path highly influence printing quality and efficiency. Conventional LCD 3D printers tend to use thumb-size COB LED with Fresnel film. This leads to less than desirable light uniformity where the light intensity is less in the edge areas. The major focus for these printers is on cost reduction. Phrozen’s own ParaLED optical engine uses an LED array matrix with the same size as an LCD panel.

Prozen also narrows down the LED emission angle to make it as parallel as possible. That way, they can increase the efficiency of light passing through the LCD’s and, therefore, improve printing speed and quality.

Z-axis wobbling is a big problem for most entry-level resin 3D printers.

You will find that the Z-axis of many 3D printers is not fixed on top (or just simply put a cap on it). Overall Z-axis design on these printers is based simply upon an optical axis and rail shaft. This results in severe wobbling during the 3D printing process, especially for large & high models.

Instead of implementing a simple optical axis and rail shaft, Phrozen uses twin linear rails, ball screws, and ball bearings with aluminum, precision CNC-machined parts on their printers, allowing them to assure linearity and minimize the impact of loaded forces during the printing process.

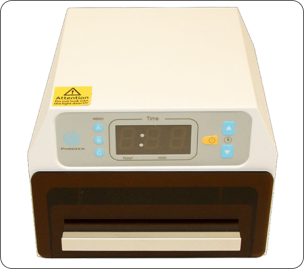

UV Light Curing Box

Final step after 3D printing

High-intensity UV light (390 – 410 nm) for post-curing, with intensity at 40 mw/cm^2. Can finish post-cure within 10 minutes, depending on your thickness

Phrozen Sonic 4K

For Dental Clinics

4K with 6.1” Printing Area: 3840 x 2160 ultra-high-definition. Prints at 35µm with 722 PPI, the highest PPI ever, with a large printing area of 6.1” Monochrome LCD Screen: Prints up to 5 times faster than traditional 3D printers, taking only one second to print a layer, twice as fast as the Sonic Mini 4K, & Multi-Resin Compatibility.

Connectivity: USB | Ethernet , Technology: Resin 3D Printer – LCD Type, Light Source: 405nm ParaLED Matrix 3.0, Layer Thickness: 0.01-0.30mm, Printing Speed: 90mm/ hour.

Phrozen Sonic 4K XL

For Dental Labs

Phrozen’s Sonic XL 4K provides a spacious printing area of 8.9,” 45% larger than Sonic 4K, allowing you to create dental models with the precision you need. With printing speeds of up to 90mm per hour, the Sonic XL 4K provides increased productivity by letting you print multiple models at once.

Monochrome LCD Technology: Engineered to cure at up to 0.2 seconds, 4K Resolution, Wireless Printing, & Multi-Resin Compatibility.

Phrozen Ultra-Sonic Cleaner

Controlling range: 20 - 80 degrees C

Ultrasonic cleaners are a reliable, safe, and effective way to remove mold support from the surfaces of a 3D-printed part. Parts manufactured by the 3D printing process can take advantage of ultrasonic cleaners to expedite the cleaning and finishing stages after a part is printed.

High-alkalinity detergent and hot water are placed in ultrasonic cleaning machines along with the part, and the resin dissolves in short order. No manual labor is needed.